The Effect of Container Materials on Production of Light Induced Off-Flavors in Milk – A Study Using SPME-GC-MS

Robert E. Shirey

Introduction

Light induced off-flavors (LIOFs) in milk became an issue when dairies began to package milk in high density polyethylene (HDPE) plastic jugs instead of glass bottles. There are several types of LIOFs with the most common coming from oxidation of lipids and degradation of sulfur containing amino acids. Light induced lipid oxidation occurs when free radicals react with the unsaturated fatty acids in milk. The free radical reaction cleaves the double bond and forms hydroperoxides that degrade predominately to aldehydes and to a lesser degree, ketones and alcohols. The most common light activated analytes in this class are hexanal and pentanal, primarily induced from linoleic acid.1

The mechanism for the breakdown of sulfur containing amino acids in whey protein is not fully understood. The most common breakdown products in this class are dimethyl sulfide (DMS), methanethiol (MT) and dimethyl disulfide (DMDS). Due to the high volatility of DMS and MT, this study focused primarily on DMDS.

It is well documented that UV rays do not easily penetrate glass, but have been known to penetrate various types of plastic materials. In the US milk is predominately sold in HDPE jugs. Some of these jugs contain white or colored pigments to increase the effectiveness of the plastic to serve as a barrier to UV light. The goal of this study was to evaluate various types of plastics to determine which type provides the best barrier for preserving the integrity of the milk.

Several analytical methods have been used for the analysis of LIOFs in milk. In this study we chose solid- phase microextraction (SPME) to analyze the various milk samples, because of its automation capabilities. Furthermore this technique is sensitive, easy to automate, and is accurate with good precision.

Materials & methods

Milk containing 2% fat was purchased from a local dairy farm and was stored in ½ gallon glass jugs with a wall thickness of approximately 5 mm. The plastic sealing cap was immediately covered with aluminum foil upon purchase and the milk was stored at 4 °C in the dark.

Different types of plastic containers were obtained from various sources throughout the lab. Each of the plastic containers contained a symbol indicating the type of plastic. Effort was taken to find containers with similar surface areas and volumes. The wall thickness of each container was measured with calipers. The containers were filled to 93% ±1% of the internal volume. The purpose was to keep the void volume of the containers consistent since the shape of the containers varied. The caps and container necks were wrapped with aluminum foil to prevent UV permeation through the cap. The container materials and dimensions are shown in Table 1.

A 500 mL volumetric flask was filled with cold milk and spiked with an internal standard, hexanal-d12, at 5 μg/L. The milk was immediately dispensed into containers at the volume levels listed in Table 1 and into two glass vials sealed and placed in the refrigerator at 4 °C. Caps were covered with aluminum foil to reduce UV permeation. The containers were placed in a foil-lined tray about 10 cm beneath Sylvania Octron 32 W fluorescent lights, which were used as a UV light source. The exposure time was 2 hours. After the milk was exposed, the containers were placed in the refrigerator at 4 °C for 1 h to cool the milk and prevent rancidity. During the time the milk samples were being cooled, ten empty 10 mL vials were placed in a Peltier-cooled vial tray holder set at 4 °C on a Gerstel MPS II multi-purpose sampler. The sampler was also equipped with a needle conditioner to clean the fiber, and an agitator for sample mixing. Five mL of milk was transferred in duplicate into ten cooled vials. The two vials containing the spiked fresh milk in the refrigerator were added to the tray. A Supelco® CAR/PDMS fiber on a Nitinol core was used to extract the samples. The extraction conditions used in the study are shown in Table 2.

The samples were analyzed with an Agilent 7890B GC connected to a 5977 A MSD. The conditions used to analyze the desorbed analytes are shown in Table 3.

Results

The CAR/PDMS fiber on the Nitinol core is an excellent choice for this application due to the small micropores of CAR/PDMS. These pores are ideal for extracting small and midsized analytes. The Nitinol core is very durable and inert. The coating process is produced with state-of-the-art coating equipment that assures good reproducibility by constant monitoring of the coating thickness. The addition of sodium chloride does increase recovery of these analytes in water, but not in milk containing fat. The responses in milk samples were higher with better precision without added salt; therefore, salt was not added to the samples. Various extraction times were evaluated, but it was determined that 15 minutes enabled samples to be quantified below μg/L concentration levels. The other SPME parameters were optimized to provide good extraction and desorption efficiencies without compromising sample integrity. A calibration curve was generated by spiking seven fresh milk samples with a standard of the LIOFs analytes from 1-10 μg/L sample concentration and with hexanal-d12 at 5 μg/L. Another vial of fresh milk was only spiked with hexanal-d12 at 5 μg/L. The samples were extracted and analyzed according to the methods listed in Tables 2 and 3. The relative responses of each analyte were calculated and the relative responses from the sample not spiked with the LIOF standard were subtracted from the seven LIOF spiked samples.

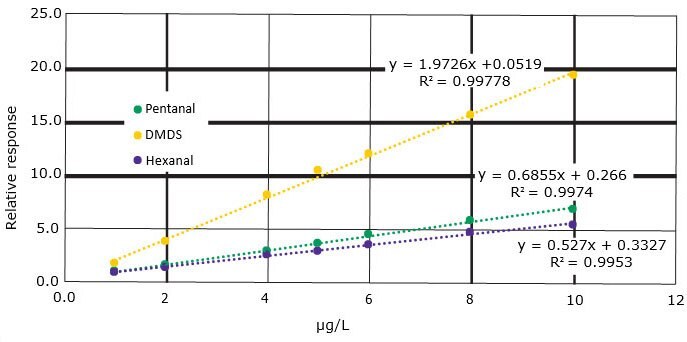

Figure 1.Calibration curve of relative responses of LIOFs with background subtraction

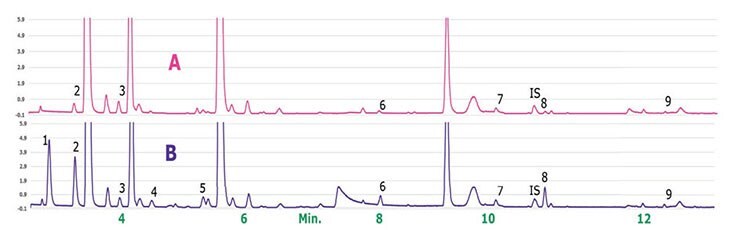

Figure 2.Chromatograms of milk spiked with IS not exposed to light (A); milk spiked with IS exposed to light stored in a polypropylene container (B).

Peak IDs: 1. Pentane; 2. Isopropanol; 3. Dimethyl sulfide; 4. n-Hexane; 5. 2-Butanol; 6. Pentanal; 7. Dimethyl disulfide; IS. Hexanal-d12; 8. Hexanal; 9. Heptanal. (See Table 3 for run conditions)

Relative responses of the three analytes over the 1-10 μg/L spiking range had regression coefficient values > 0.99, and low Y‑intercept values (Figure 1). These results were obtained in full scan mode, so greater sensitivity could be obtained using SIM mode if needed. Chromatograms of milk not exposed to light spiked with the IS (A) and milk exposed to light in a polypropylene container (B) are shown in Figure 2. The comparison of the chromatograms shows that light exposure in the PP container increased the response of many of the analytes. Both chromatograms are at the same scale, and the response of the internal standard (hexanal-d12) is similar in both plots. Even though this study focused on three analytes, other analytes are generated from the light exposure or some other mechanism. Two small volatile analytes, pentane and isopropanol, have much larger responses on the light exposed samples. Note that the samples were run in duplicate (data not shown here) and the responses of duplicate samples were similar. To calculate the concentration level of the selected LIOFs obtained from milk exposed in the various containers, the average relative responses from duplicate runs were calculated. The average relative responses are shown in Table 4.

The average relative responses for each analyte obtained from the no light exposed milk samples were subtracted from the average relative responses obtained from the various containers. The background subtracted relative responses were divided by the slope of the line as listed in Figure 1. Figure 3 shows the calculated results.

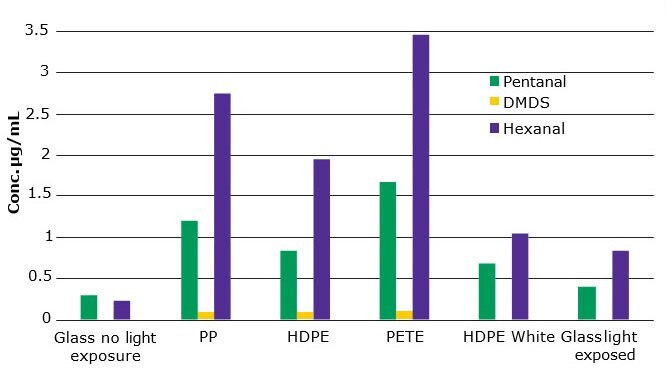

Figure 3.Concentration in μg/L of LIOFs in milk with background subtraction.

The results show that two of the plastics, PETE and PP, were the least efficient barrier to UV light. The PETE container had the thinnest wall of the containers, which may have contributed to the barrier properties. PP had the thickest wall of any plastic but the formation of LIOFs was quite high. The addition of white pigment to the HPDE plastic made it a much better barrier to UV light. Its properties were similar to glass. The thickness of the glass does affect the barrier properties as we demonstrated in an additional study.

Conclusions

The type of material used to store milk can be critical in the prevention of lipid oxidation. This study shows that glass is still the best barrier to UV light, but HDPE impregnated with a pigment is a good option. In this case white pigmentation helped to reduce LIOF formation, but studies have shown that yellow or pink pigments may be even better. The CAR/PDMS fiber on the Nitinol core was able to retain the small flavoring analytes. The micropores retain and release these analytes efficiently. In addition, the Nitinol core is highly inert and extremely durable. This fiber is a viable alternative to this coating on a fused silica core.

References

如要继续阅读,请登录或创建帐户。

暂无帐户?