Millipore® Filter Membranes

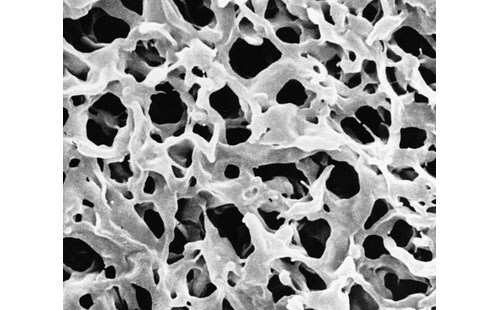

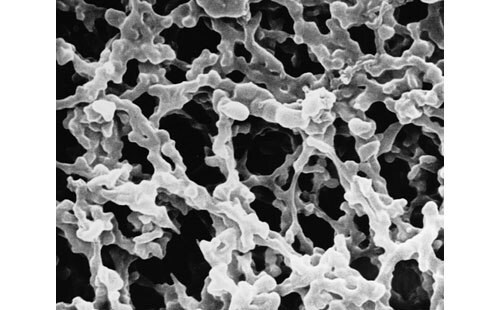

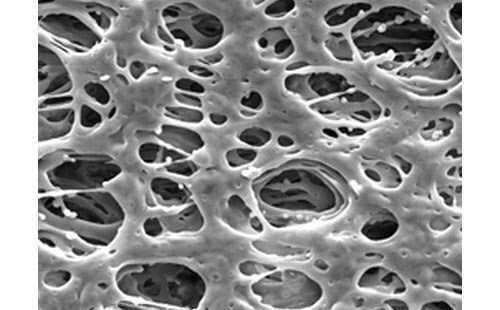

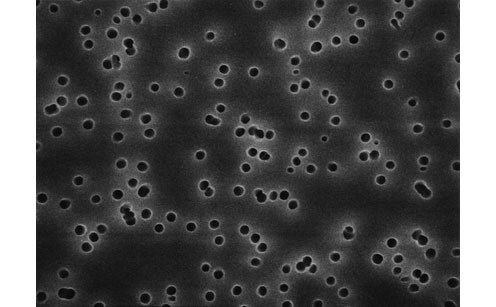

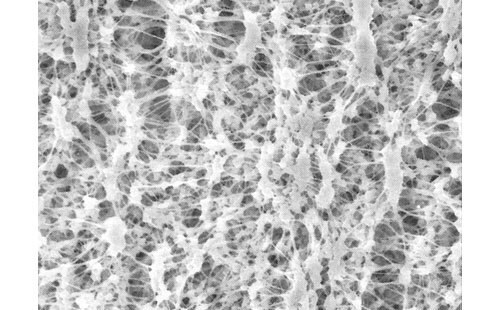

Membrane filters, produced by precipitation or stretching of polymeric materials, are used for a variety of applications (e.g. filtration, air particle monitoring). Properties of membranes differ markedly based upon their composition, fabrication method, surface treatment, and pore size.

NEED HELP FINDING THE CORRECT MEMBRANE FILTER FOR YOUR APPLICATION?

Use our Membrane Learning Center tool to view and compare membranes by pore size, chemical compatibility, flow rate, extractables and more.

Products

Membrane Filter Characteristics

- Chemical Compatibility: The filter material must be compatible with the chemical nature of the substance being filtered to avoid structural failure. It is important to consider both the compatibility of liquid samples and dissolved solutes that can interact with the membrane.

- Wettability: For liquid filtration, the membrane must be wettable with the fluid being filtered. Hydrophilic membranes are easily wet with water and are preferred for filtering aqueous solutions. Hydrophobic membranes are recommended for gas filtration, low surface tension solvents, and venting, and can be wet in organic solvents such as methanol, allowing filtration of both aqueous liquids and organic solvents.

- Pore Size: Pore size provides an indication of the largest pore diameter and can be related to the membrane’s ability to filter out particles of a certain size. Bubble point and bacterial retention testing are two commonly used methods for measuring pore size.

- Diameter: The diameter, size, and shape of the filter are selected based on the apparatus used for filtration or sample collection.

- Flow Rate: Defined as the time required for the flow stream to pass through the filter, flow rate may be measured for air or liquid. Flow rate generally decreases with smaller pore size, but altering membrane material, thickness, porosity, and pore architecture can lead to differences in flow rate.

- Analyte Binding: Analyte binding refers to the loss of analytes during filtration, resulting in a filtrate with a different molecular composition than expected. Membranes with limited functionality (e.g. PVDF, PTFE) show very low analyte binding, whereas membranes with higher functionality (e.g. nylon, MCE) show a high level of analyte binding)

- Optical Properties: When visually analyzing retentates, membrane optical properties must be compatible with the imaging method, such that the membrane provides a consistent background over the entire sample surface and does not impart additional noise during testing.

- Extractables: Extractables are contaminants present in the final filtrate that originate in the filter or device. Filter extractables occur as three different types: shedding of filter materials or particulate extractables, residual chemicals from the manufacturing process, and surface modification chemistries washing off the filter. The presence of extractables can also be related to the chemical compatibility of the membrane with the solution being filtered. Generally, if a membrane is not chemically compatible with the solution, a higher level of extractables is observed in the filtrate.

- Retentiveness: Retentiveness is the ability of a membrane to retain the particle or molecule of interest.

Prefiltration and Depth Filters

- Prefiltration: Prefiltration utilizes large pore membrane filters to remove large particulates, such as dirt or sediment, from samples prior to filtration with a smaller pore membrane filter. Using prefiltration in sample preparation can prevent premature filter clogging or fouling.

- Depth filters: Depth filters retain particles internally rather than on the filter surface. Due to their high particle retention capacity, depth filters are frequently used for prefiltration.

- Binders: Commonly used in non-woven, fiber-based materials, binders provide shape and strength to the final product. While binders are routinely used in glass fiber filters, these additives reduce thermal stability and can result in sample contamination by extractables.

- Net Filters: With large and uniform pores, the net-like structure of net filters is used to remove large particulates (e.g. cells, proteins, dirt) for solution clarification of particulate analysis.

Filter Membrane Types

- Reinforced cellulose membranes (RW filters) are rigid screen filters. Their rigidity, high-capacity, and low pressure drop make RW filters ideal for the removal of contaminants from heavily contaminated liquids and gasses, particularly for prefiltration.

- Cellulose support pads are used to reinforce filters in monitors for contamination analysis, specifically during high pressure or fast flow conditions. When saturated with growth medium, they can also be used for microorganism culture. Woven mesh spacers are placed between filters during serial filtration to prevent the downstream screen filter from “blinding” the upstream filter pores, increasing flow rate and throughput.

- Glass fiber filters are produced from borosilicate glass fibers and are typically used to filter large particles or viscous solutions. In addition to a wide variety of flow rates and capacities, we also offer filters both with and without binder resin. While the addition of binder resin improves the wet strength for filtering heavily contaminated solutions, the resin renders the filter unsuitable for gravimetric analysis or hot gas filtration due to mass loss upon heating. Glass fiber filters without a binder resin can be heated up to 500 °C without mass loss.

- MF-Millipore™ mixed cellulose esters (MCE) membrane filter discs, produced from biologically inert cellulose acetate and cellulose nitrate, are a versatile choice for biological, analytical, and environmental monitoring as well as research applications. With a consistent thickness, uniform pore structure, and smoother surface than pure nitrocellulose membranes, hydrophilic MF-Millipore™ membranes are available in a variety of pore sizes, colors, surfaces, and diameters. MFMillipore™ membranes without Triton® surfactant contain minimum amounts of wetting agent and have a lower water extractable content than standard MF-Millipore™ filters.

- Nylon membranes and net filters ** are made from the same material but utilize two different processing methods. Due to this difference, nylon net filters possess a uniform, large pore structure (similar to a mesh), a pore size ≥5.0 μm, and a reduced thickness in comparison to nylon membrane filters.

- Isopore™ polycarbonate membrane filters offer well-defined pores and a smooth transparent surface ideal for use with optical or electron microscopy.

- Millipore Express® PLUS polyethersulfone (PES) membrane filters are commonly used as an alternative to cellulose membranes and are known for their thermal stability, durability and resistance to acidic and alkaline solutions. Millipore Express® PLUS PES membranes offer fast flow, high filter capacity and low protein binding, while remaining bacterially retentive. The unique asymmetric structure of Millipore Express® PLUS membranes extends filtration capacity and lifetime, allowing them to tolerate higher particle loads and protein concentrations.

- Millipore® polypropylene membranes and net filters feature both solvent-compatibility and thermal stability. Constructed from pristine polypropylene material, these filters are ideally suited for general solution clarification and prefiltration applications, including bioburden reduction. Millipore® polypropylene membrane and net filters provide high particle retention and dirt holding capacity, as well as a low pressure drop.

- Polytetrafluoroethylene (PTFE) ** is a chemical-resistant, flexible, thermally resistant, non-adherent, high-strength fluoropolymer produced from the free-radical polymerization of tetrafluoroethylene. Due to its strength and broad chemical compatibility, PTFE is commonly used in membrane filters. While PTFE is known for its high strength, the addition of a high-density polyethylene (HDPE) backing offers improved filter handling characteristics. Hydrophilic LCR and Omnipore™ PTFE membranes are typically used for filtering aqueous solutions. Both Fluoropore™ hydrophobic PTFE and Mitex™ hydrophobic PTFE membranes can be used for filtering organic solvents and gases. Fluoropore™ membranes and PTFE for PM2.5 are also used for particle monitoring.

- Millipore® polyvinylidene chloride (PVC) membranes, due to their low weight and low water adsorption, are preferentially used with gravimetric analysis to quantify silica, carbon black, or quartz air particulates. Millipore® PVC membrane filters are produced from high-quality PVC and have been developed for use with ASTM, NIOSH, and OSHA air monitoring methods.

- Durapore® polyvinylidene fluoride (PVDF) filter membranes, available in both hydrophilic and hydrophobic formats, provide high flow rates and throughput, low extractables and broad chemical compatibility. Due to their solvent and heat resistance, Durapore® PVDF membranes are utilized in a variety of biomedical research applications. Hydrophilic Durapore® membranes exhibit very low protein binding as compared to nylon, nitrocellulose or PTFE membranes. Hydrophobic Durapore® filter membranes exhibit high protein binding.

- Quartz fiber filters are manufactured from pure quartz fibers, preventing any surface filter reaction with acidic gases. Due to their inertness, quartz fiber filters are well suited for measuring heavy metal concentrations and small particle quantities. Quartz fiber filters also exhibit good weight and form stability.

- Silver membrane filters, made from pure silver, are highly resistant to thermal stress and aggressive chemicals, while providing a low background for sensitive X-ray diffraction analysis. Silver membranes are specified in many standardized air monitoring methods from government organizations (e.g., NIOSH, OSHA) for monitoring carbon black, coal tar products, coke oven emissions, and silica.

- Strat-M® membrane is a synthetic, non-animal based model for transdermal diffusion testing that is predictive of diffusion in human skin without lot-to-lot variability, safety or storage limitations.

Related Product Resources

User Guide: Chemical Compatibility of Filter Components

Brochure: Experience the Unmatched Predictability of Strat-M Membrane

Data Sheet: AD030 Air and Fluid Particle Monitoring Guide

Article: AD030 Particle Monitoring Guide – Analysis Techniques – Microscope-Based Techniques

Article: Millipore® Patch Test Kit: Field-Based Sampling and Contamination Analysis

Article: Retentate filtration with Millicup™-FLEX disposable vacuum filtration units

Catalog: Filters and Supporting Hardware

To continue reading please sign in or create an account.

Don't Have An Account?